Energy-Saving Thermal Insulation

Aerogel

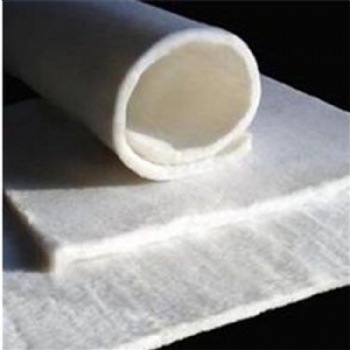

- Aerogel felt is the main material of nano-silica aerogel, which is made of glass fiber or preoxidized fiber felt.

- It is characterized by low thermal conductivity, a certain amount of tensile strength

- and compressive strength, which is convenient for thermal insulation construction

- and belongs to a new type of insulation material.

- INQUIRY

Profile

Aerogel blanket area is about 400 ℃ temperature minimum thermal conductivity of solid insulation (400-1000 ℃ high temperature coefficient of thermal conductivity is much higher than micro-nano insulation series)

Aerogel blanket with soft, easy to cut, density is small, inorganic fire prevention, the overall hydrophobic, green environmental protection features, such as the alternative to glass fiber products, asbestos insulation felt, silicate fibre products such as environmental protection, traditional flexible about the worse performance of heat preservation heat preservation material.

Aerogel blanket is mainly used for industrial piping, storage tank, the industrial furnace, power plant, capsule, warships bulkhead, bullet trains, buried pipes, injection molding machine, the removable type insulation sleeve, heavy oil exploitation of high temperature steam pipe, transportation, household appliances, steel, non-ferrous metal, glass, and other fields of heat preservation and heat insulation.

Physical properties of

Package form: volume

Thickness: 2mm, 3mm, 4mm, 5mm, 6mm, 10mm

Width: 910mm, 1500mm

Density: 180 ~ 220kg/m cubed

Applicable temperature: 200 ℃, + 1000 ℃ (same model)

Hydrophobic: absolute hydrophobic (below 350 ℃)

Coefficient of thermal conductivity: 0.012-0.018 w/m k. (25 ℃)

Merit

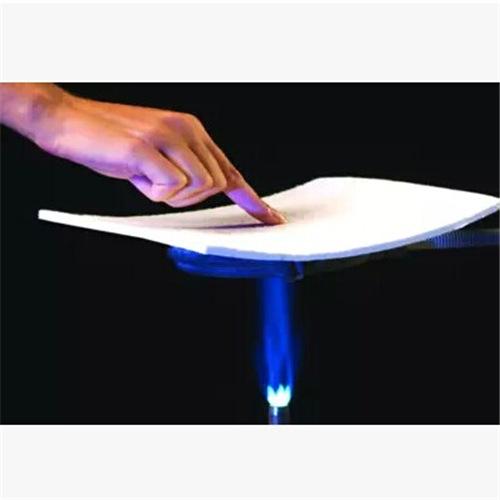

1. Excellent thermal insulation effect

The insulating effect of aerogels is 2-5 times that of traditional thermal insulation materials. According to the theory of Arrhenius' experiment, the theoretical life is 20 years. Almost identical to the life of the building.

2. Reduce insulation thickness

The aerogel blanket has the same insulation effect and is only a fraction of the thickness of traditional materials. The heat loss is small and the space utilization is high. At high temperature, the above performance advantages are more obvious.

3. Hydrophobic and fire resistance

The aerogels are absolutely water-repellent, which can effectively prevent water from entering the pipe and inside the equipment. Have fire prevention performance level building A1, at the same time and aerogel unique three-dimensional network structure to avoid the other insulation materials used in high temperature for a long time such as sintering deformation and subsidence in the heat preservation effect is significantly lower.

4. Convenient construction

Aerogel felt light, easy to cut and sewn to suit various shapes of pipes, equipment insulation, and installation required time and manpower less.

5. Savings in transportation costs

Smaller package size and lighter weight can greatly reduce the transportation cost of insulation materials.

typical application:

Industrial field: Petroleum extraction, petroleum refining, thermal power plant pipeline insulation

Furnace insulation

Cold preservation of LNG and other cryogenic pipelines

Prefabricated insulation pipe

Application in the field of construction

Roof insulation

House floor insulation application

Equipment and facilities Die casting furnace field

Rescue cabin insulation

Car engine and exhaust pipe insulation

Thermal insulation of steam turbines, valves, etc.

More details and any inquiries pls contact us:

Email: bruce@hbwaner.com

Tel/WeChart/WhatsApp: +86-15732429783

Categories

Contact Us

Tel:+86-15732429783

Mobile:+8615731175596

E-mail: admin@hbwaner.com or bruce@hbwaner.com

Whatsapp: +86-15731175596 or +86-15732429783